hidden

-

Strategic

PRINT SOLUTIONS

Wright Business Graphics is the leading printing source dedicated to providing you with printed products that exceed your expectations.

From design concept through folding and gluing, our folding carton team offers a cohesive approach to the entire process. Need a design prototype quickly? Not a problem for our Structural Design team.

Utilizing an array of digital presses with varying format sizes, color configurations and the latest technology, we offer tailor made products for a multitude of market applications.

For longer runs of color rich commercial printing, our sheetfed presses are perfectly suited for catalogs, magazines, direct mail and marketing pieces of all kinds with coating options and bindery all in house.

From continuous and unit set forms to cut sheets and laser forms, we do it all. We manufacture four-color process and up to 10 spot color business forms and commercial cut sheet web products in addition to printing business statements, invoices, checks and letterheads on a variety of stocks.

We also work to ensure that our check security features are among the latest and most effective in the industry. As a result, our hidden void pantos are some of the best. The stock patterns in the recommended colors pass ANSI standards and are image qualified on site. With our vast security feature options and customizable patterns and prismatic effects, our checks have some of the most current advances in fraud deterrent techniques.

Wright’s Critical Communications Division operates as a self-contained business unit specializing in the processing and delivery of sensitive and personally identifiable information (PII). Wright CCD provides secure data processing and multi-channel delivery from our high-security controlled environment. CCD has implemented an automated document factory model which minimizes data access and maximizes efficiency by utilizing automation. We have the ability to deliver high-volume, variable, critical communications with a focus on printed first class USPS transactional mail. CCD commonly processes complex jobs requiring custom programming and integration, which differentiates Wright CCD from typical “mail houses”.

Personalized graphic communication, whether online or print, has been proven to increase response rates, shorten response times, and increase the size and frequency of purchases.

Reach out to target audiences through a variety of media platforms with our cross media solutions. Whether it’s print, web, e-mail or mobile messaging, you can now deliver relevant and consistent marketing to your audience through the media type they prefer.

A secure Digital Asset Management solution full of capabilities that automate and streamline common tasks, clearing the way for creative and marketing teams to work faster and deliver more impact by making it easy to organize, share, approve, distribute and track.

We offer warehouse storage and distribution at each of our production facilities that can be tailored to your client’s needs. In most cases, release requests in by noon can ship same day via most all common carriers.

Advancing your reputation as you communicate with customers, prospects, and employees.

For 50 years, we've been behind the scenes helping businesses of all kinds meet their needs.

We accept all current industry-standard graphic file formats including PDF, InDesign, Illustrator, Photoshop, QuarkXPress, TIFF, EPS, JPG

For optimal print quality, your images should be 300 dpi and scaled at 100%

As a general rule, any graphics that reach the trim should be extended an additional ⅛ inch

Ideally, trim marks should be placed ⅛ inch passed the trim edge. Any closer and there might be edit charges added to the job

All files supplied must be colored with the ink colors you intend to use for final print, which should only consist of the following types...

Also known as "process colors"

Use official PANTONE naming convention (e.g. PANTONE 185 C)

Use names that make it easily identifiable

Use the name "Dieline"

Use "Variable" and colorize as a contrasting Spot Color

Use names that make it easily identifiable (e.g. Spot UV )

All PDFs are not the same nor do they guarantee quality results if they're not made correctly and from a good source. Even still, PDFs are not truly considered print-ready until they successfully process through our prepress workflow. As an integral part of our internal quality control process, we use the expressions below in our communication to help distinguish between those differences.

Desktop PDF - Supplied from an unknown source and not checked for any compatibility

Production PDF - Verified, Workflow Optimized and Ready for Printing

For all jobs that we die-cut, our CAD department will supply you with the final die file to incorporate into your art. This will usually be supplied as a layered Illustrator PDF format with the die-cut layer locked. Do not attempt to manipulate the die-cut layer in any way. After you integrate your art to it, verify the die-cut art is named as "Dieline" and is colorized as a Spot color.

Also, we recommend that you review your separations for accuracy by using the Adobe Separation Preview panel.

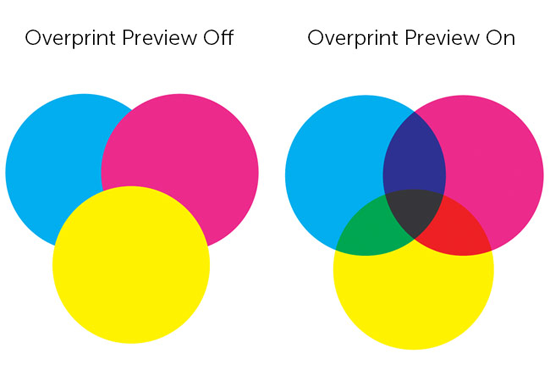

Have you ever opened a PDF file, and the colors are inaccurate or missing? Before you panic, check your settings to make sure that overprint preview is turned on in your Adobe Acrobat. Overprinting happens when a file is designed utilizing two or more colors to create a third color instead of knocking out the bottom layers. In order to view the print output of this effect on-screen, overprint preview has to be turned on. If the file has any spot colors and/or transparency blending effects, it is very important that overprint preview is turned on to accurately view any mixing of transparencies with spot colors. We highly recommend that your settings always default to overprint preview on. By turning overprint preview on, you are automatically changing the settings to high-resolution display as well.

Go to Acrobat > Preferences > Page Display

Under "Page Content and Information", the "Use Overprint Preview" dropdown menu, confirm or change to be set to Always, then click OK

Go to Edit > Preferences > Page Display

Under "Page Content and Information", the "Use Overprint Preview" dropdown menu, confirm or change to be set to Always, then click OK

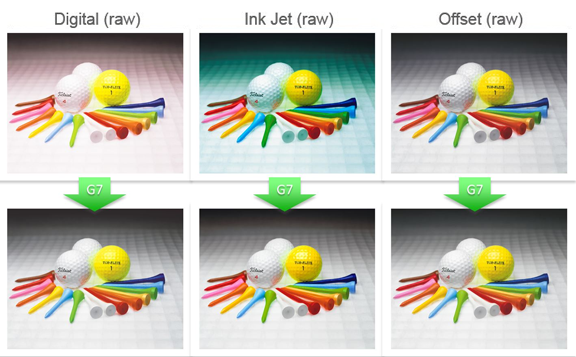

Although simple in concept, process color printing is a complex manufacturing challenge. As brands and agencies become more global and media-savvy, they will increasingly require visually consistent color output across all devices and types of printing. The G7 process helps produce visually consistent CMYK color output (at the very least) across all devices and types of printing.

We have 5 manufacturing facilities located in Portland, Seattle metro (Kent) and Los Angeles metro (Chino).

Yes. We adhere to strict environmental standards and are certified by the Forest Stewardship Council® (FSC®).

Wright’s Critical Communications Division is SOCII TYPE 2 compliant. We have implemented hundreds of physical, administrative and technical controls to safeguard customer data and ensure effective operations. We focus not only on operations but on the privacy, confidentiality and security of customer supplied data. CCD conducts an annual 3rd party review of these controls.

We'd love to hear from you.